Top-Rated Aluminum Stamping Parts

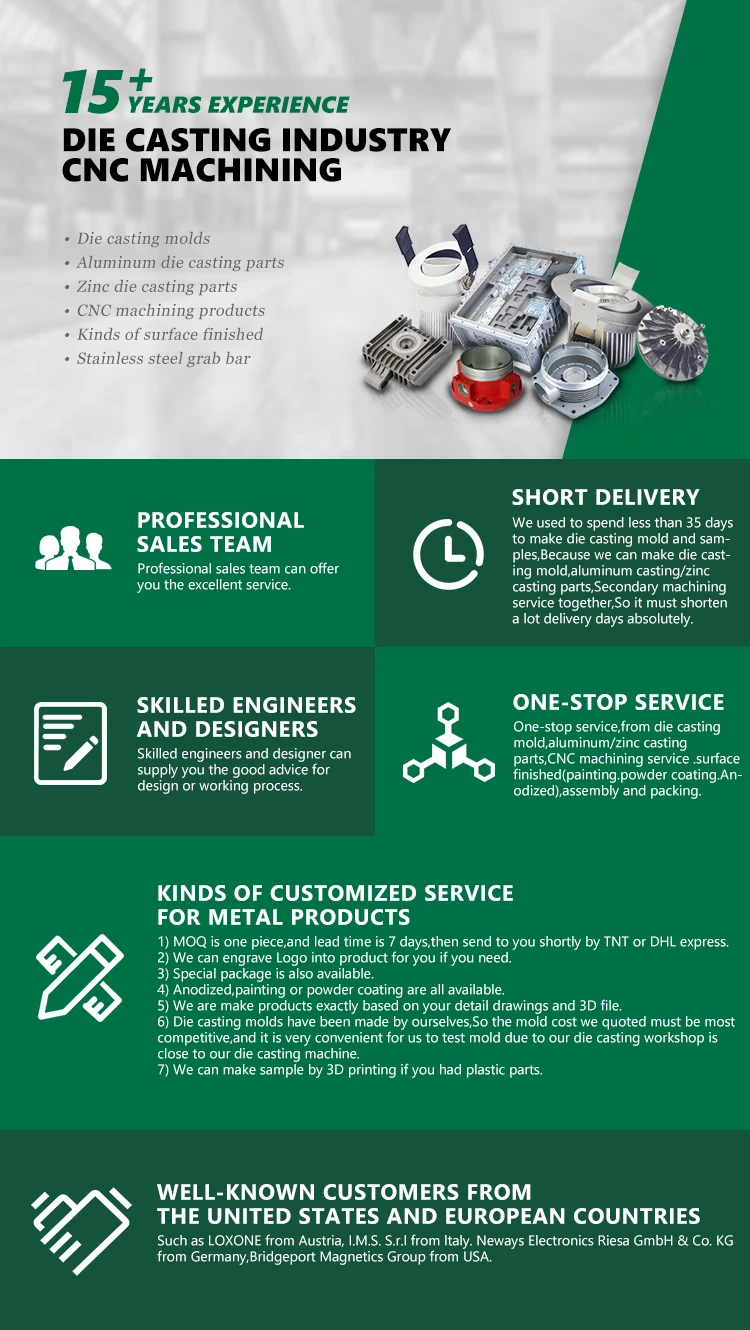

Producing the best aluminum stamping parts requires using high strength to weight ratio raw materials and the most reliable machining tooling, among other essential equipment. We have invested in these resources because we always want our metal stamping products to have the best features, making them easier for you to sell.

We also monitor the final products the ensure they have excellent aluminum stamping capabilities and other benefits like corrosion resistance and durability.

There is a high demand for aluminum alloys and products of precision metal stamping like the standards we provide. Also, you will find more customers asking for custom metal stamping products. We encourage you to partner with us for easy access and continual supply of the best stamped aluminum components used in different markets.

What Makes our Aluminum Cube Socket Stand Out?

As always, we aim to be the best manufacturers of commercially pure aluminum products like these cube sockets. So, we have gone the extra mile to ensure this cube socket is the best option for your project. To achieve a flawless aluminum stamping project, we guarantee the following benefits when using these cube sockets:

Corrosion Resistance

The aluminum alloys used as raw materials to make these cube sockets are not prone to corrosion. Also, they are usable in several industries, especially when a sheet metal stamping press is involved. Making them corrosion resistant is an assurance your customers will use them satisfactorily and for many years.

Impressive Tolerance Level

The tolerance level of aluminum alloys is one feature that makes them desirable for making various parts needed in different industries. Since we use only high-grade aluminum alloys to make our products, the tolerance level is exceptional. Also, we can adjust the tolerance level to match your custom metal stamping parts according to the project.

Production Experience

Using all those complicated machining tools for precision metal stamping parts and getting the best results when the sheet metal comes out requires experience. We have the best sheet metal stamping team producing these cube sockets for a global market.

We are proud to state that these cube sockets can be shipped and used in different parts of the world where common aluminum alloys and aluminum components are needed.

Product Description – OEM Custom Large Cube Socket

The custom large cube sockets are the best stamped metal parts because we focus on the properties the end users want. Here’s why these large cube sockets stand out:

Tight Tolerances

We ensure the tolerances match the production brief, so our customers are satisfied with the final results.

Best for Safety Railings

The metal materials are sturdy and match the properties of specialized alloys. The cube sockets hold fast when used for projects. This means the stamping parts will not fall apart after completing the job.

Accurate Dimensions

Working with these cube sockets is easy because their dimensions are accurate and can match complex parts involved in the project. Pure aluminum is also an added advantage.

Overall, these large cube sockets are one of excellent products from our aluminum die casting processes. And they are always available on the market.

Order in Bulk

You can order these cube sockets today. Send us your customer contact form, and we will quickly process and ship your order.

Q1. Can I have a sample order for Die casting product?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Q3. Do you have any MOQ limit for Die casting product order?

A: Low MOQ, 1pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order for Die casting product?

A: Firstly let us know your requirements or application. Secondly We quote according to your requirements or our suggestions. Thirdly customer confirms the samples and places deposit for formal order. Fourthly We arrange the production.

Q6. Is it OK to print my logo on Die casting product?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: Do you offer guarantee for the products?

A: Yes, we offer 2-5 years warranty to our products.

Q8: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 0.2%. Secondly, during the guarantee period, we will send new lights with new order for small quantity. For defective batch products, we will repair them and resend them to you or we can discuss the solution i ncluding re-call according to real situation.